Ingabe unaso isipiliyoni sokusebenzisa amathuluzi omshini we-CNC anembayo (njengezikhungo zokumaka, imishini yokukhipha ugesi, imishini yezintambo ezihamba kancane, njll.) ezimbonini zokwenza imishini enembayo ephezulu? Lapho uqala njalo ekuseni ukwenza imishini, ukunemba komshini wesiqephu sokuqala ngokuvamile akwanele; Ukunemba kweqoqo lokuqala lezingxenye ezicutshungulwe ngemva kweholide elide kuvame ukungazinzi, futhi amathuba okuhluleka ngesikhathi somshini wokunemba aphezulu aphakeme kakhulu, ikakhulukazi mayelana nokunemba kwendawo.

Amafekthri angenawo umuzwa wokwenza imishini enembile ngokuvamile afaka ukunemba okungazinzile ezinkingeni zekhwalithi yesisetshenziswa. Amafekthri anesipiliyoni sokwenza imishini esinembayo azonamathisela ukubaluleka okukhulu kumazinga okushisa emvelo kanye nokulingana kwe-Thermal kwamathuluzi omshini. Kucace bha ukuthi ngisho namathuluzi omshini anembe kakhulu angakwazi ukufeza ukunemba komshini ozinzile kuphela ngaphansi kwemvelo ezinzile yezinga lokushisa kanye nokulingana kwe-Thermal. Ukushisa kuqala ithuluzi lomshini kuwulwazi oluyisisekelo kakhulu lwemishini yokunemba lapho ukukhiqizwa komshini wokunemba okuphezulu kudinga ukuqaliswa ukusebenza ngemva kokuqaliswa.

1, Kungani sidinga ukushisa kuqala ithuluzi lomshini?

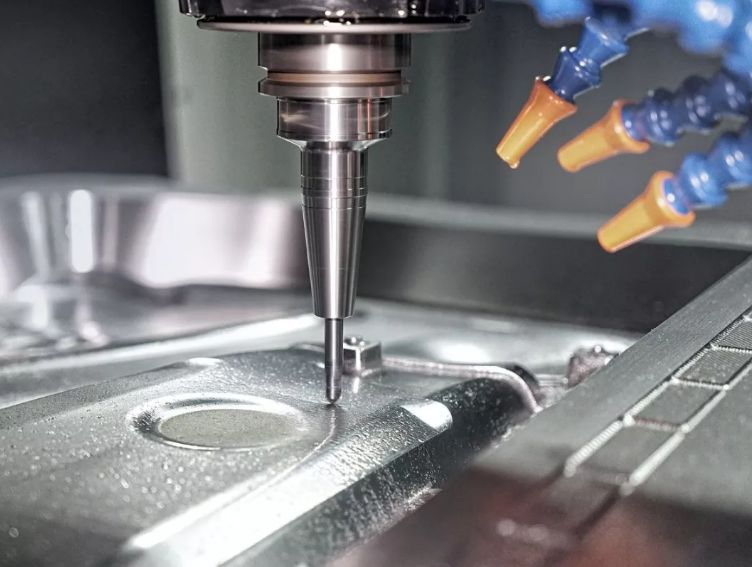

Izici ezishisayo zamathuluzi omshini we-CNC zinomthelela omkhulu ekunembeni komshini, okubala cishe uhhafu wokunemba komshini. Amarayili omhlahlandlela, izikulufu, nezinye izingxenye ezisetshenziswa ku-spindle kanye nezimbazo ezinyakazayo ze-X, Y, kanye no-Z zethuluzi lomshini zizokwenyuka izinga lokushisa nokonakala ngenxa yokulayisha nokushwibeka phakathi nokunyakaza. Kodwa-ke, ochungechungeni lwephutha lokushintshwa kwe-thermal, umthelela omkhulu ekunembeni komshini ukugudluzwa kwama-axes anyakazayo angu-X, Y, kanye no-Z ahlobene nebhentshi lomsebenzi.

Ukunemba komshini wethuluzi lomshini esimweni sokuvala shaqa isikhathi eside kanye nokulingana kwe-Thermal kuhluke kakhulu. Isizathu siwukuthi izinga lokushisa le-spindle kanye ne-axis ngayinye ehambayo yethuluzi lomshini we-NC kugcinwa ngokulinganayo ezingeni elilinganiselwe ngemva kokusebenza isikhathi esithile, futhi njengoba isikhathi sokucubungula sishintsha, ukunemba okushisayo kwethuluzi lomshini we-NC kuvame uzinze, okubonisa ukuthi kuyadingeka ukushisa i-spindle kanye nezingxenye ezihambayo ngaphambi kokucubungula.

Kodwa-ke, ukulungiswa kwe-"Warming up" yamathuluzi omshini kuye kwanganakwa amafektri amaningi.

2, Indlela yokushisa ithuluzi lomshini?

Uma ithuluzi lomshini lingasebenzi isikhathi esingaphezu kwezinsuku ezimbalwa, kunconywa ukuthi ushise kuqala okungenani imizuzu engama-30 ngaphambi komshini wokunemba okuphezulu; Uma isimo sokungenzi lutho singamahora ambalwa kuphela, kunconywa ukuthi ushise kuqala imizuzu engu-5-10 ngaphambi komshini wokunemba okuphezulu.

Inqubo yokushisisa kwangaphambili ihlanganisa ukubandakanya ithuluzi lomshini ekuhambeni okuphindaphindiwe kwe-eksisi yokwenza imishini, okungcono kakhulu ngokusebenzisa ukuxhumana kwama-eksisi amaningi, njengokuhambisa ama-eksisi X, Y, kanye no-Z ukusuka ekhoneni elingezansi kwesokunxele lesistimu yokuxhumanisa ukuya ekhoneni eliphezulu kwesokudla, futhi ukuhamba ngokuphindaphindiwe nge-diagonally. Ngesikhathi sokubulawa, uhlelo lwe-macro lungabhalwa ethuluzini lomshini ukwenza ngokuphindaphindiwe isenzo sokushisa. Isibonelo, lapho ithuluzi lomshini we-CNC limiswa isikhathi eside noma ngaphambi kokucutshungulwa kwengxenye yokunemba okuphezulu, ngokusekelwe kwijika lepharamitha yezibalo ze-3D kanye nebanga lesikhala lethuluzi lomshini wokushisa, t isetshenziswa njengokuhluka okuzimele, kanye nezixhumanisi ama-axes anyakazayo u-X, Y, kanye no-Z asetshenziswa njengezinto eziguquguqukayo zepharamitha. Ngokwesinyathelo esithile sokunyuswa, ububanzi obukhulu bezimbazo ezinyakazayo ze-X, Y, kanye no-Z busetshenziswa njengesimo somngcele wejika lepharamitha, kanye nesivinini sokuphotha kanye no-X, Y Isivinini sokuphakelayo se-Z-axis sihlotshaniswa ne- okuhlukile okuzimele t, okuwuvumela ukuthi uguquke ngokuqhubekayo phakathi kwebanga elithile, okukhiqiza uhlelo lwe-CNC olungabonwa ithuluzi lomshini we-CNC. Isetshenziselwa ukushayela i-eksisi ngayinye enyakazayo yethuluzi lomshini ukuze ikhiqize ukunyakaza okungalayishi okuvumelanayo, futhi kuhambisane nezinguquko zokulawula isivinini sokuphotha kanye nesivinini sokuphakela ngesikhathi senqubo yokunyakaza.

Ngemuva kokushisa okwanele kwethuluzi lomshini, ithuluzi lomshini eliguqukayo lingafakwa ekukhiqizeni imishini yokunemba okuphezulu!

Isikhathi sokuthumela: Aug-02-2023