Isigayo sokuphela kwe-carbide CNC efakwe usimende

Incazelo emfushane:

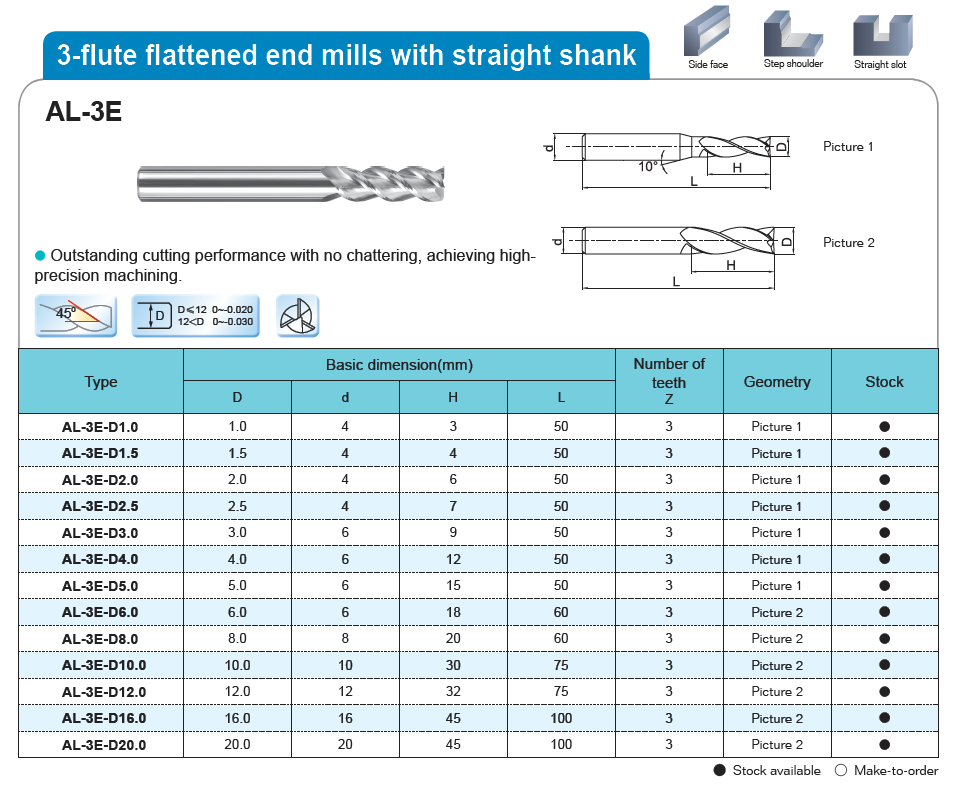

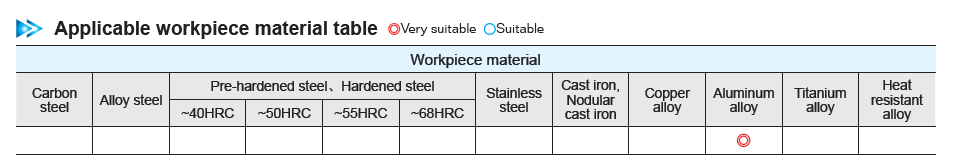

Uchungechunge lwe-AL 3-umtshingo wesigayo esicaba esinomshini oqondile we-shank ofaneleka kakhulu ukwenziwa kwe-AL.

Sinolwazi olunzulu olusebenzayo kulo mkhakha futhi singakunikeza cishe izinhlobo zezigayo eziqinile ze-carbide.

AL uchungechunge Isingeniso

Izigayo zokuphela kochungechunge lwe-AL ze-AL machining.AL izigayo zokuphela kochungechunge zingamathuluzi okusika okusebenza okuphezulu adizayinelwe izinhlelo zokusebenza zokugaya. Zenzelwe ukususa ngokuphumelelayo izinto ezisetshenziswayo futhi zinikeze isiphetho esihle kakhulu sangaphezulu kanye nokunemba kobukhulu. Izigayo zokuphela kochungechunge lwe-AL zakhiwe ngezinto zekhwalithi ephezulu njenge-carbide eqinile noma insimbi yesivinini esikhulu ukuze iqine futhi iphile isikhathi eside. Lezi zigayo zinemiphetho yokusika eqondile futhi ziza ngezinhlobonhlobo zejometri njengesikwele, ikhala lebhola, irediyasi yekhona kanye namaphrofayili amabi. Idizayini yomtshingo yezigayo zokuphela kochungechunge lwe-AL ithuthukisiwe ukuze inikeze ukuphuma okusebenzayo kwe-chip, ukuvimbela ukwakheka kwe-chip nokunciphisa ukukhiqizwa kokushisa ngesikhathi somshini. Lokhu kusiza ukunweba impilo yamathuluzi nokugcina ukusebenza kokusika okungaguquki. Ukucushwa komtshingo kungase kuhluke, kuhlanganise nemiklamo emibili, emithathu noma emine yomtshingo, kuye ngezidingo ezithile zomshini. Izigayo zokuphela kochungechunge lwe-AL zitholakala ngamasayizi ahlukahlukene, amadayamitha nobude ukuze zivumelane nemisebenzi ehlukene yomshini nezinto zokusebenza. Zivame ukusetshenziswa ezimbonini ezihlukahlukene ezihlanganisa i-aerospace, izimoto, ukwenza isikhunta, kanye nezicelo zemishini evamile. Sekukonke, izigayo zokuphela kochungechunge lwe-AL zingamathuluzi okusika athembekile futhi ahlukahlukene ahlinzeka ngokusebenza okuphezulu kokusika, ukunemba nokuqina kwemisebenzi ehlukahlukene yokugaya.

Ikhwalithi ephezulu yamathuluzi kanye nokukhishwa kwama-chips amahle kuthuthukisa izimo zokusika futhi kwandise kakhulu impilo yamathuluzi.

Isikhwama se-chip esinomumo oyingqayizivele senza ukusebenza okuhle kakhulu ngisho nasemshinini we-slot kanye nomgodi.

Unqenqema lokusika olucijile kanye nomklamo omkhulu we-engeli ye-helical kuvimbela ngempumelelo unqenqema olwakhiwe.

Idizayini ye-anti-vibration yonqenqema lonke ingacindezela ukuxoxa ngesikhathi somshini futhi ithuthukise ikhwalithi yendawo.

Uhlobo lwethuluzi:AL-3E-D6.0 Ubukhulu:Ø6.0mm

Impahla yokusebenza: LC4

Isivinini esijikelezayo: 13000r/min (250m/min)

Isivinini sokuphakelayo:1950mm/min (0.15mm/r)

Ukujula kokusika kwe-axial:ap=9.0mm

Ukujula kokusika kwe-Radial: ae=1.0mm

Isitayela sokusika:I-complicated cavity machining

Ukupholisa uhlelo: air blow

Ithuluzi lomshini: MIKRON UCP 1000

Ipharamitha

Isicelo

FAQ

Ngokusho komumo sinezinhlobo eziningi kakhulu, njenge-flattened end mill, i-radius end mill, i-ball nose end mill, i-high-feed-rate end mill, i-long neck end mill, i-head end mill encane njalonjalo.

Okuhlukile okuyinhloko izidingo zokucubungula: izigayo zokugcina ngezokugaya, kanti izingcezu zokubhoboza zingezelelwe ukubhoboza nokubuyisela kabusha. Nakuba kwezinye izimo, umsiki wokugaya angaphinda abhoboze, kodwa akuyona into evamile.

Uma uhlobo esinalo esitokweni, noma yiliphi inani lizolunga.

Yebo, singakwenzela ngokwezifiso njengezidingo zakho.

Okokuqala, i-workpiece material.

Okwesibili, imininingwane yokwakheka nobukhulu:ububanzi be-shank, ububanzi bomtshingo, ubude bomtshingo kanye nobude obuphelele, inani lamazinyo.

Okwesithathu, uma udinga ngokwezifiso, sinikeze umdwebo kuyoba ngcono.