1912 Winter Ice Antiskid Grip Snow Screw Tractor Tyre Stud

Incazelo emfushane:

Ama-studs angashumekwa ngokuqondile endaweni yesondo ukuze kuthuthukiswe ikhono lokulwa nokushushuluza nokusebenza kokuphepha kwezimoto. Inhloso yabo eyinhloko ukuhlinzeka ukudonsa nokuzinza okungcono, ikakhulukazi ezindaweni lapho kunobusika obude neqhwa elinzima kanye nokunqwabelana kweqhwa.

Izikhonkwane zamasondo zinezinhlelo zokusebenza eziningi ezihlukene, ezifaka ukusetshenziswa emicimbini yokuncintisana efana nemiqhudelwano yamazwe ngamazwe kanye nezinhlanga zamarali, lapho izimoto zivame ukudinga ukubamba okuphakeme nokulawula ezindaweni eziyinselele. Ukwengeza, ama-spikes abuye asetshenziswe ezimotweni zobunjiniyela ezisebenza ngaphansi kwezimo ezinzima, lapho ukuthuthukiswa kokudonsa kubalulekile. Izinhlobo ezahlukene zamasondo ziyatholakala ukuze zivumelane nezinhlobo zamathayi ahlukahlukene kanye nezidingo ezithile.

Lezi zikhonkwane zingenziwa ngendlela oyifisayo futhi ziklanywe ukuthi zihambisane nanoma yiluphi uhlobo lwesondo lemoto, ngisho nezinye izinto ezisetshenziswayo njengamabhuzu okugibela izintaba nezigxobo zokushushuluza, ezithuthukisa ukusebenza kwazo endaweni eneqhwa noma eneqhwa.

Ukwakheka komkhiqizo

| Igama | Izikhonkwane zamasondo eCarbide | Izinhlobo | 1912 | |

| Isicelo | Forklift, Ugandaganda, Lahla iloli, Grader, Crane | Iphakheji | Isikhwama sepulasitiki/ibhokisi lephepha | |

| Okubalulekile | Iphinikhodi ye-Carbide noma iphinikhodi ye-cermet +umzimba wensimbi ye-carbon | |||

| Umzimba we-studs | Material: Carbon steel Ukwelashwa kwendawo : Galvanization | |||

Iseluleko

Uma ukhetha usayizi ofanele wamasondo amasondo, kufanele ulinganise ukuphakama kwe-protrusion yephethini yesondo. Ukufaka izigxobo zamasondo emoto ngokuvamile kudinga amathuluzi akhethekile nekhono, njengoba ukufakwa okungafanele kungase kulimaze isondo noma kubangele ukugibela okungazinzile. Ukwengeza, ezinye izindawo zingase zibe nemithethonqubo efanele evimbela ukusetshenziswa kwezigxobo zamasondo emoto, ngakho-ke udinga ukuqonda imithetho yendawo kanye neziqondiso ngaphambi kokuzisebenzisa.

Izici

① 98% iyathuthuka ekumelaneni nokushelela

② Uhambo oluphephile noluthembekile

③ Iphinikhodi ye-carbide eqinile

④ Kulula ukufaka nokususa ⑤Idizayini enkulu yomumo ovunguzayo kanye nenqubo yokushisela yethusi inikeza ukubamba okungcono ukuvimbela ukushelela. ⑥Ukuthengisa okushisayo e-Europe naseMelika

Amapharamitha

98% THUTHUKISA EKUMELENI KWE-SLIP

I-Wide auger Screw-ln Tire Ifanele 1912# Ifanele zonke izinhlobo zezimoto zokwakha emigwaqweni enodaka eqhweni naseqhweni

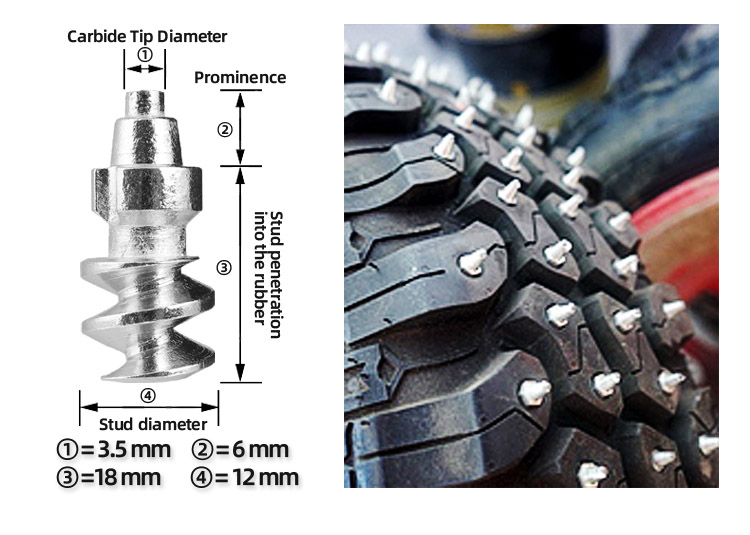

Amapharamitha womkhiqizo (UNIT:mm)

| Uhlobo Lomkhiqizo | 1000 | 1100 | 1200 | 1300 | 1400 | 1500 | 1600 | 1700 | 1740 | 1750 |

| Isithombe somkhiqizo |  |  |  |  |  |  |  |  |  |  |

| I-Dimensions Diameter X Ubude Obuphelele | 6X8.4 | 7.9X9.8 | 9x12.6 | 9x15.2 | 9x16.3 | 9x17.5 | 7.7x16.6 | 9x20.8 | 7.7x17.4 | 7.7x20.9 |

| Ukuvelela | 2.2 | 1.9 | 1.9 | 3.2 | 2.8 | 4 | 3.6 | 7.3 | 5.4 | 6.9 |

| Ukungena Kwe-Stud Ku-Rubber | 6.2 | 7.9 | 10.7 | 12 | 13.5 | 13.5 | 13 | 13.5 | 12 | 14 |

| Izinyathelo Ezincane Zokunyathela Ngokujwayelekile | 5 | 5.9 | 8.5 | 9.5 | 11 | 11 | 10.5 | 11 | 9.5 | 11.5 |

| I-Carbide Tip Diameter | 1.7 | 2.2 | 2.6 | 2.6 | 2.6 | 2.6 | 2.2 | 2.2 | 2.2 | 2.2 |

| Uhlobo Lomkhiqizo | 1800 | 1800R | 1900 | 1910 | 1910T | 1911 | 1912 | 3000A | 3000B |

| Isithombe somkhiqizo |  |  |  |  |  |  |  |  |  |

| I-Dimensions Diameter X Ubude Obuphelele | 9x23.3 | 9x24.5 | 9x20.5 | 10x19 | 10x23.8 | 11x22.8 | 12x24.5 | 7.9x15.1 | 7.9x11.4 |

| Ukuvelela | 6.8 | 8 | 4 | 4.5 | 5.3 | 5.3 | 6 | 4.4 | 3 |

| Ukungena Kwe-Stud Ku-Rubber | 16.5 | 16.5 | 16.5 | 14.5 | 18.5 | 17.5 | 18.5 | 10.7 | 8.4 |

| Izinyathelo Ezincane Zokunyathela Ngokujwayelekile | 14 | 14 | 14 | 11.5 | 16 | 14.5 | 15.5 | 7.5 | 5.8 |

| I-Carbide Tip Diameter | 2.6 | 2.6 | 2.6 | 3 | 3 | 3.5 | 3.5 | 2.2 | 2.2 |

Ukufakwa

FAQ

Khetha usayizi ofanele futhi uyifake ngendlela efanele, ngeke ibhoboze amathayi. Ngoba ukujula kokufakwa kuvame ukufana nobude bephethini yerabha yokunyathela .Ungaphinda uyiqaqe ethayini uma ungayisebenzisi.

Izikhonkwane zamathaya sezivele ziyizinhlobo zemikhiqizo evuthiwe. Isetshenziswa emhlabeni wonke eYurophu naseMelika. Ukuyifaka nokuyisebenzisa ngendlela efanele ngeke kube nomthelela empilweni yamathayi. Uma kungenjalo, amathayi ngokwawo ayasebenziseka, kunezidingo ezithile mayelana nemikhawulo yobudala kanye namaKilomitha ahanjiwe. Kudingeka sikuhlole futhi sikushintshe njalo.

Uma ushayela emgwaqeni oneqhwa, kulula ukushelela . izinsimbi zamasondo zingakugcina uphephile. Ifakwe ebusweni berabha yesondo ngokuqondile, yenza uzinze ngokwengeziwe. Thuthukisa ukunamathela, wenze ukushayela kuzinze, kungasheleli.

Amathiphu: izigxobo zamasondo azinawo amandla onke. Ukuze uphephe ekuhambeni kwakho, Ukushayela ngokucophelela kubaluleke kakhulu.

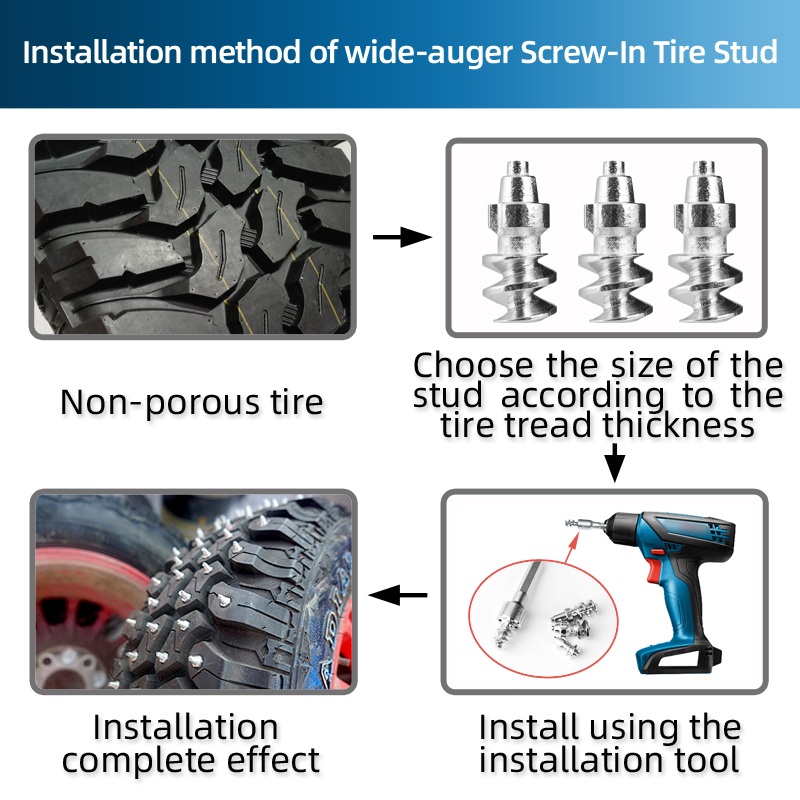

1). Amathayi anembobo, singakhetha izikhonkwane zamasondo e-rivet shape noma izikhonkwane zamasondo enkomishi. Amathayi angenambobo, singakhetha izikhonkwane zamasondo eziyisikulufa.

2). Sidinga ukukala ububanzi bembobo nokujula kwamasondo (amasondo anembobo); idinga ukukala ukujula kwephethini yerabha yokunyathela ethayini lakho (amasondo angenayo imbobo), bese ukhetha izigxobo ezifanelekela isondo lakho.

3). ngokuya ngedatha yesilinganiso, singakhetha usayizi wezikodi ngokusekelwe kumathayi akho kanye nokuhamba komgwaqo ohlukile wokushayela. Uma ushayela emgwaqeni wedolobha, singakhetha usayizi omncane wokuvelela. Uma ushayela emgwaqeni onodaka, endaweni enesihlabathi nendawo yeqhwa eliwugqinsi, singakhetha usayizi omkhulu wokuvelela, okwenza ukushayela kuzinze kakhudlwana.

Ngokujwayelekile ama-studs angama-80 kuye kwangama-480 isondo ngalinye, futhi ungawafaka ngokuya ngokuthanda kwakho. Yiqiniso, uma kuthe xaxa, ngcono umphumela wokushelela.

Akuyona inkinga ukufaka izigxobo zamasondo uwedwa. Kulula uma kuqhathaniswa. Ungayifaka ngesandla noma usebenzise amathuluzi kagesi ukuze uthuthukise ukusebenza kahle. Sizokuhlinzeka ngevidiyo yokufaka.

Ingasuswa ngokuya ngesizini, futhi ingahlakazwa uma ungaphinde usetshenziswe ngesizini elandelayo.